Windable shows a new way to track shipped packages using inexpensive paper-based electronics located on one side of a shipping label.

Makes his debut at CES 2025the technology uses paper-based electronics, which have been around for some time – I wrote about it back then Xerox has partnered with Thinfilm in 2015 to produce printed circuits on thin materials. But nearly a decade later, the cost of this type of infrastructure has fallen, allowing Reelables to embed 5G and GPS tracking electronics into a shipping label along with a coated zinc battery.

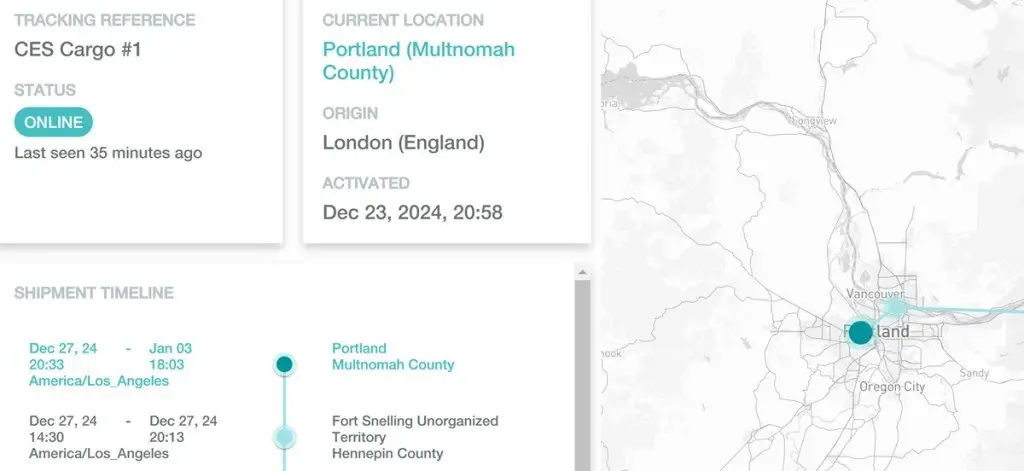

Nowadays it is possible to track packages, but you have to trust that the shipping company will do this correctly for you, and often they only tell you which city the packages are in. This allows you to determine where the packets are located on 5G cellular connection. This means that when it reaches its destination, you know and have peace of mind that what you sent to someone actually got there.

If your package goes off course or is stolen by someone, you can also find out and report the theft. This may not result in you receiving the package back. But it could give you more confidence in the entire shipping system.

The company will unveil the product at CES 2025 in the LVCC North Hall, Booth 8364.

How it works

In an industry first in printed electronics, Reelables will unveil its latest ultra-thin, printable cellular shipping labels at CES, Reelables founder Brian Krejcarek said in a message to GamesBeat.

He said these smart tags look like regular UPS or FedEx tags, but connect to cellular networks to track packages and cargo live with real GPS location data, independent of the carriers. They don’t rely on cumbersome and error-prone barcode scanning by delivery drivers or warehouse workers, he said.

“This is a game-changer as this new category of smart labels does not require the installation of expensive RFID readers or infrastructure,” Krejcarek said. “The range of typical passive RFID tags is only 10-15 feet or less. The range of Reelables’ active beaconing labels is similar to that of a cell phone connecting to cell towers miles away. Or, in the case of Reelables Bluetooth labels, the range is several hundred feet. This means they are able to perform an inventory check of an entire warehouse every ten seconds.”

He said GPS tracking devices have been around for some time, but the form factor of an actual label and cost allow for the first time mass deployment to track almost anything, not just high-value goods. The label is less than 0.5 millimeters thick and can be printed using standard barcode printers. This means no new workflows or training are required. Simply print, stick and mail, like companies already do today, Krejcarek said.

Reelables has developed the technology and manufacturing capabilities in-house to produce these active smart labels like adhesive tape with aircraft-safe, coated zinc batteries at scale and is in production today. Unlike lithium battery-based devices, Reelables labels are aircraft-safe, non-hazardous goods and are clearly classified as packaging materials by U.S. Customs and Border Control, he said.

No return logistics are required. As a study by shows Westrock and Western Michigan University, Paper Pilot PlantAccording to Krejcarek, the labels on corrugated cardboard can be disposed of in regular trash and do not require e-waste disposal.

Only now is there widespread 5G cellular infrastructure for the Internet of Things (like NB-IoT from AT&T and Vodafone) along with thin-film printed electronics technology that brings this printability, recyclability, and soon a sub-$10 price tag, inclusive of the label, enables connectivity and tracking service, said Krejcarek. As you can see from the cover image of this story, Krejcarek could see the exact path a package took to get from one destination to another. You’ll see this on your package’s tracking page.

Reelables doesn’t use Thinfilm or British company Pragmatic because the flexibility isn’t needed since the chips it uses are so small. Instead, Reelables has figured out how to use common silicon-based wafer chips for the RF chipsets and bond them directly to the substrate with an epoxy resin in a complete reel-to-reel process without soldering.

“At Reelables, we produce millions of active beaconing Bluetooth and cellular tags in-house using direct-coated zinc batteries, meaning the active electrochemical parts of the battery share the same substrate as the actual RF circuitry for Bluetooth and NB-IoT,” he said Krejcarek. “The zinc batteries coated on our substrate means our labels are non-hazardous and are suitable for aircraft use. They can also be disposed of through normal recycling streams and do not need to be treated as e-waste.”

Source link