Or take a look at the RM 65-01, a chronograph with high octane inspired by motorsports, which recently received a gene z-friendly with versions in banana yellow, baby blue or soft gray. The colored material has the lightness and feeling of plastic, but is many times stronger than stainless steel.

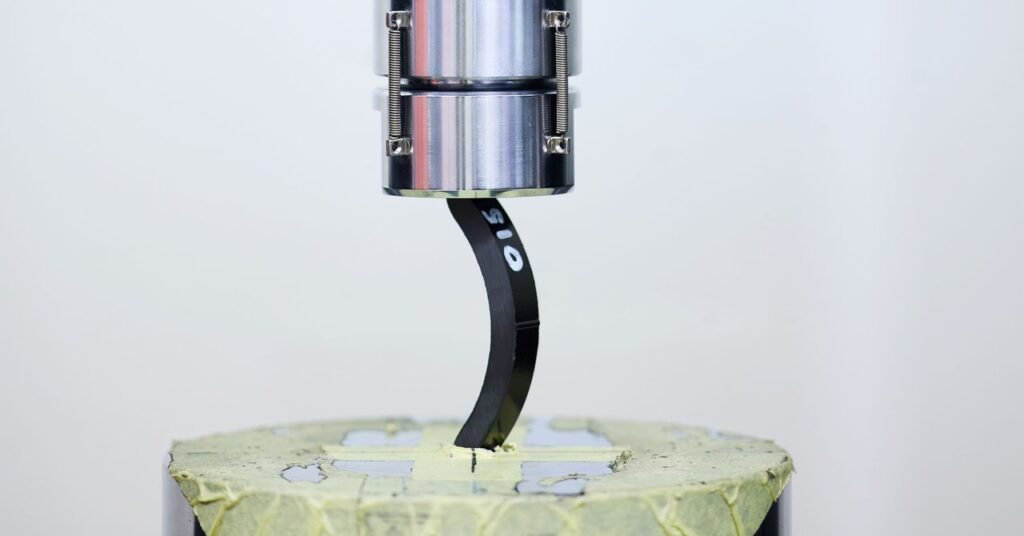

For both companies, the cooperation has become a decisive business card, so that a committed facility was opened in the NTPT headquarters of NTPT 2018, only to make Richard Mille Watch cases. Behind the glass walls of this purely white inner sanctuary, a large robot printer repeatedly shifts back and forth along a large table and diligently places precisely precise stripes made of sticky -looking material on a flawless surface. Employees in White Overalls are administering the machines, while the coils of transparent fibers flow into devices in a mysterious way, which they process in microdünne layers of “UD” (Unidirectional Band), the stuff that the machine deposits.

For Richard Mille it turned out that color and texture actually represented the by -product of a challenge that the brand of the same name of the brand was more than a decade. The company already turned Richard Mille Watch Cases out of its carbon variant Carbon TPT, but Mille asked to open the template, says Thomassin. “He said he wanted a composite for a pure white case, so we started experimenting. We actually had a red. “

Most composite materials on glass fiber base think of Kevlar, glass fiber or forging carbon, the basic principles with materials such as concrete or MDF: tiny strands of a given material are set in a bind matrix, usually a polymer resin like epoxy. The mixture is shaped, compressed and heated. The resulting composite material is typically very light and extremely strong, whereby the fibers serve as a structural reinforcement for the surrounding matrix.